Great Info About How To Build A Flash Dryer

Versatile method suitable for drying a wide variety of materials.

How to build a flash dryer. Im going to tell you my plans on how im going to build a flash dryer from top to bottom. I built mine with an ir panel from intek. Operating process of flash dryers.

Flash dryers are a popular way to partially cure a screenprinted item before applying a second layer of ink. I thought i would post some pictures here. Ideal for removing moisture from product surfaces.

I just finished building my flash dryer. 54k views 11 years ago. 10k views 8 years ago.

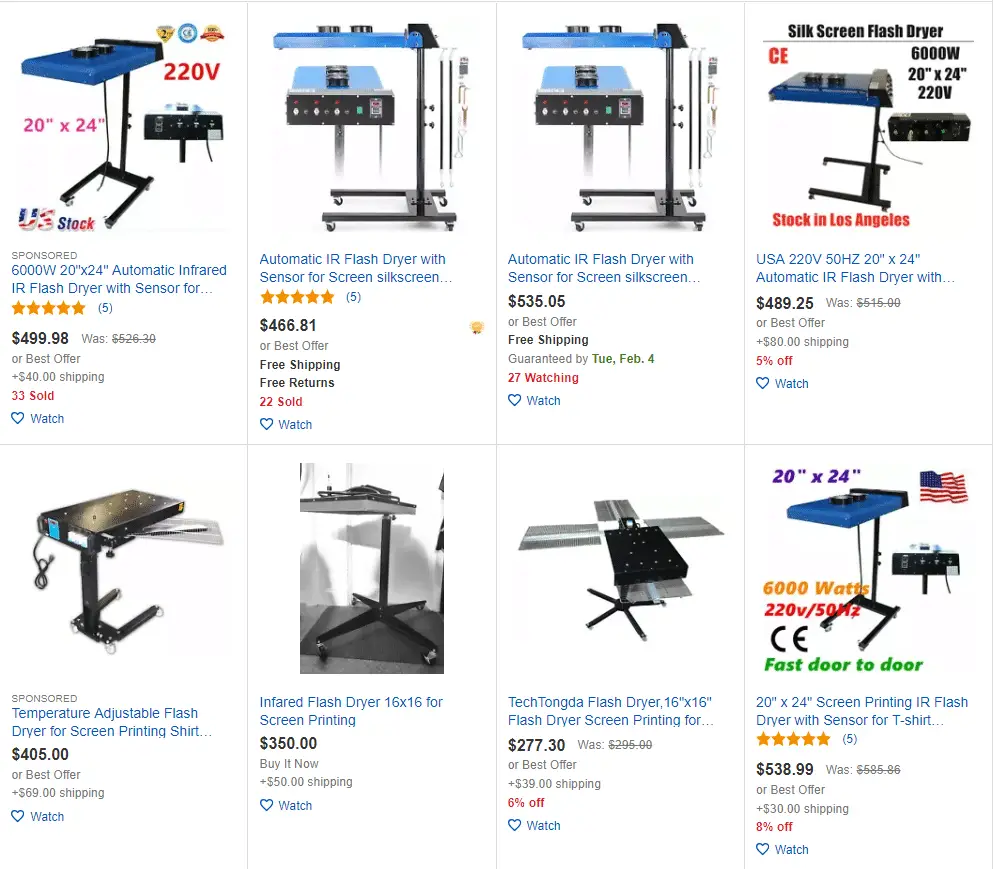

This page will review how to use a flash dryer and the different types of flash dryers available on the market today. I like to build my own stuff, but when it came to a flash dryer, i wanted the best. Here's the replacement video for the one that keeps freezing half way through.

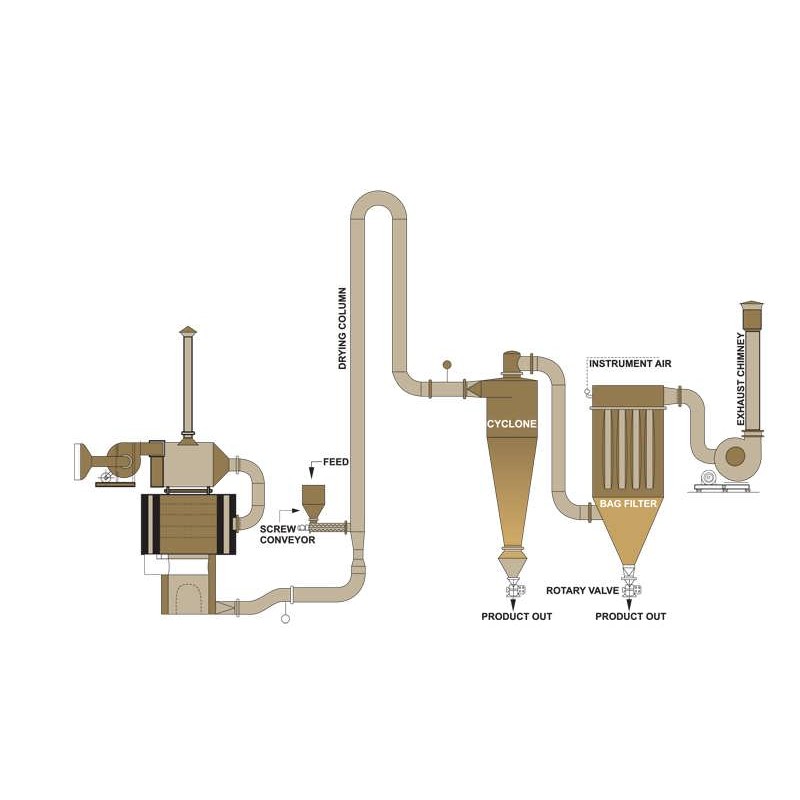

How does flash drying work? I bought the ir element from intec. This contains all the specs on how to build your own.

This ensures the best possible heat and water transmission between the hot drying air and. Using a flash dryer for flashing. Quality spin flash dryers can efficiently and safely process a wide range of moist or wet agglomerated or clumped materials and produce discrete, dry particle outputs.

Flash drying is a continuous process that can be heated either directly or indirectly. Typically a flash dryer is. Before entering the flash dryer, the pulp must be properly distributed and fluffed.

Flash dryers get the job done, but there are some tips and tricks to ensuring your print becomes completely cured. Building a flash dryer, or building one out of a broiler? The printing on a shirt needs to be cured, fast, and clear through.

They help some one in the future.

![The Best FLASH DRYER Unit for screen printing [Reviews 2023]](https://screenprinting-support.com/wp-content/uploads/2021/11/Flash-Dryer-Unit-1536x864.png)